Welcome to Yili(China)Metal Materials Limited

Tel:+8618053187167 Email:sales02@yilimetal.com.cn

PRODUCTS

Tel:+8618053187167

Email:sales02@yilimetal.com.cn

WhatsApp:+8618053187167

Address : BUILDING 1JINXIU PLAZA,ZHONGJIAN JINXIU PLAZA,HUAIYIN DISTRICT,JINAN CITY,SHANDONG PROVINCE,CHINA

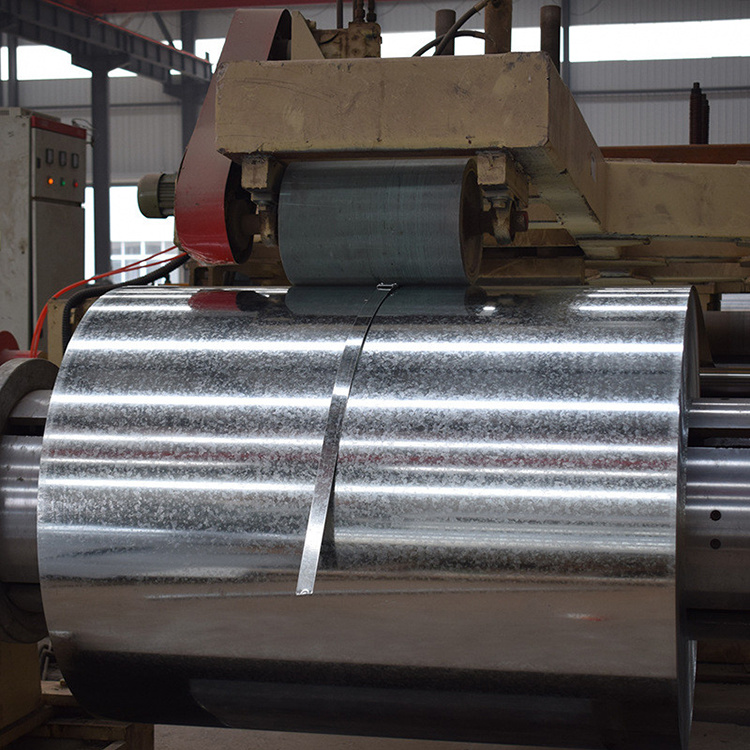

Hot dipped galvanized steel coil is made of carbon steel coated in zinc utilizing the hot-dip process. The end result of this process is a layer of zinc on each side of the steel coil that is tightly adhered to the steel through the formation of an iron-zinc alloy bonding layer. This bonding layer is formed by a diffusion process while the heated steel is in contact with molten zinc.

View More

SGCC galvanized coils are mainly used in construction, transportation, light industry, agriculture, marine and other fields, such as building exterior walls, roofs, highway guardrails, refrigerators, air conditioners, etc.

View More

Galvanized coil G550 belongs to high-strength series galvanized sheet, with high requirements for tensile strength and yield strength. Its minimum yield strength is 560Mpa, minimum tensile strength is 650Mpa, and zinc layer thickness is 275g/m2.

View More

Surface state: Because of the different treatment methods in the plating process, the surface state of the galvanized plate is also different, such as ordinary zinc flowers, fine zinc flowers, flat zinc flowers, zinc flowers and phosphating surface.

View More

DX51D galvanized sheet material is a non-ferrous alloy mainly composed of zinc as the matrix and other elements. The main alloy elements are aluminum, copper, magnesium, etc. Zinc alloy has low melting point, good fluidity, easy plastic processing and welding, and is resistant to atmospheric corrosion. According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. The commonly used cast zinc alloy is zinc aluminum copper magnesium alloy. Its casting process performance is good, and the cooling rate has little impact on the mechanical properties. It is mainly used to manufacture mechanical parts, toys, decorations, household appliances, etc.

View More

Hot dipped galvanized steel coil is made of carbon steel coated in zinc utilizing the hot-dip process. The end result of this process is a layer of zinc on each side of the steel coil that is tightly adhered to the steel through the formation of an iron-zinc alloy bonding layer. This bonding layer is formed by a diffusion process while the heated steel is in contact with molten zinc.

View More

We use optional cookies to improve your experience on our website, including through social media connections and to serve personalized advertising based on your online activity. If you reject optional cookies, we will only use cookies that are necessary to provide you with the service.